DOZOR mobile weighing system features:

- Transmitting information about the total weight of the load and axial loads to the display of the weight controller;

- Ability to print weighing results using a modern printer;

- Prompt notification of the manager about the weight of the cargo;

- Sound alert when the specified maximum weight is exceeded;

- Full control over the work and full reflection of all information about the work of trailers, bunkers - the ability to receive sms messages with weighing results;

- Possibility of fixing to a microSd card and transferring information in the amount of the transported cargo;

- Real-time data transmission (GPS, GSM);

Advantages of the DOZOR Mobile Weighing System:

- Convenient control of the weight level when loading / unloading equipment;

- field weighting;

- Control of equipment underload, with loss of cargo during transportation;

- Yield control, fertilizer use;

- Control over transport overload, increase its engine life;

- Save time - no need to decide on a stationary scale;

- High weight accuracy;

- Exclude theft (log hidden weighted);

- Exclusion of the influence of the human factor on the weighing readings;

- No overweight penalties, because in Ukraine there are large fines for overloading the vehicle axle (from 8.5 thousand to 34 thousand rubles). );

- Absolute system mobility;

- Improving the efficiency of vehicle and fleet workload;

DOZOR weight system set:

DOZOR 1 weight system

- Controller;

- Interface device;

- Tension (air) sensors (4 or 6);

- Printer for printing weighing results in the form of a check;

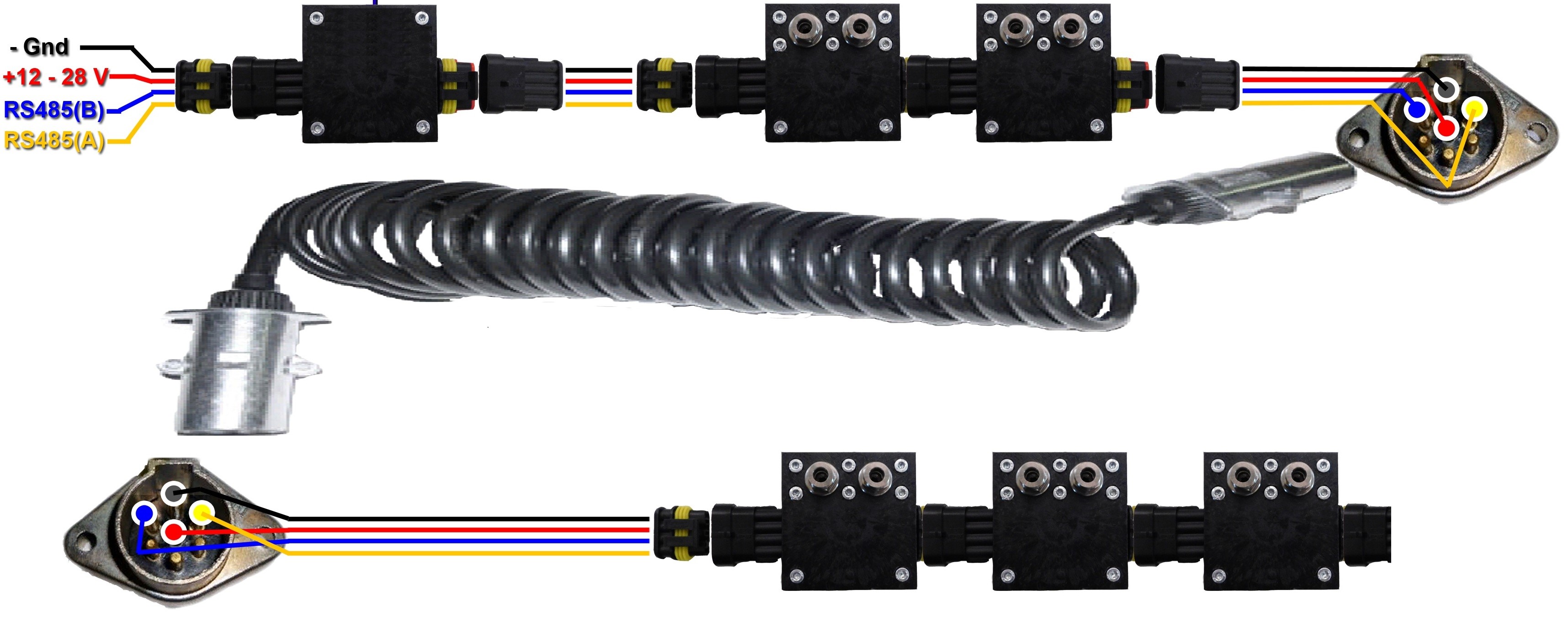

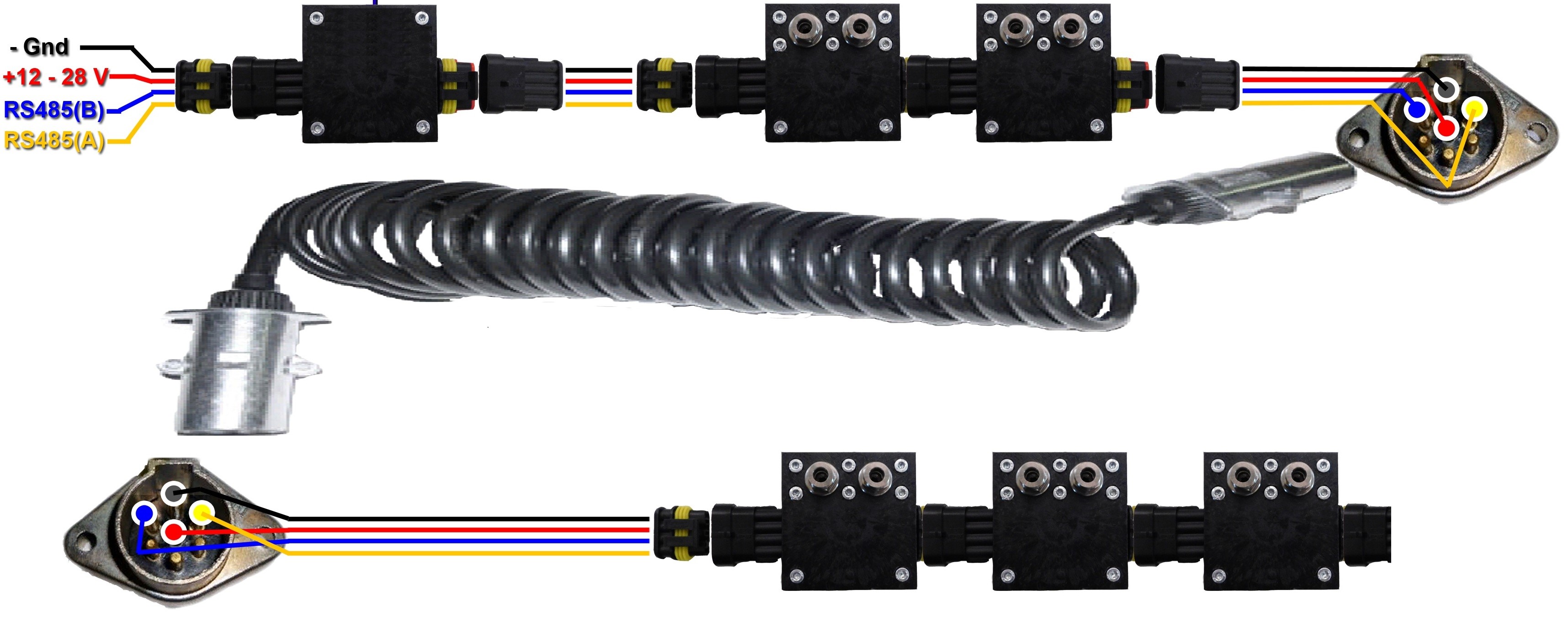

- Join box;

- Cable;

DOZOR 2 weighing system (GPS and GSM)

- controller;

- operator terminal;

- pressure (air) sensors (4 or 6);

- thermal printer for printing weighing results in the form of a check;

- junction box;

- cable;

- Transfers information on-line to the Agrosystem program.

How does the DOZOR weight system work?

There are two most common options for installing an onboard weighing system on a vehicle:

-

Using strain gauges

-

Using pneumosensors (pressure sensors)

Strain gauges

Strain gauges with the main primary device for converting the physical quantity of weight into a normalized electrical signal. The signal from the load cell is processed by the controller.

These systems are used in enterprises:

- agricultural;

- food;

- chemical;

- mining;

- compound feed production.

Load cells are installed between the machine frame and the superstructure frame (Body, trailer, hopper, etc.). All loads on the bunker, trailer, etc. are transferred to the chassis frame with the help of load cells. The electrical signals from each load cell are transmitted via cables to the controller and a device installed in the driver's cab, where all signals are converted into displays of the unit of weight (Kg). All impressions are displayed on the screen of the device and can be printed on a printer.

Air Sensors

Used for the weight system for:

- cargo & nbsp; cars;

- trailers;

- semi trailers;

- grain trucks;

- tippers.

The & ndash; axle and body load control system is a weight system that is suitable for any trucks with any type of suspension.

The principle of operation of the weighing system is based on the use of data from pneumatic sensors , fixing changes in the vehicle's suspension. These systems allow operational control of weight characteristics of transport during the whole movement. & Nbsp;

Pneumatic sensors are built into the pneumatic lines of a tractor or trailer using a specialized adapter, converting the obtained air pressure values into suspension and transmit them to the display, depending on the system configuration, via cables or radio channel.