Farm Dog and John Deere announced the beginning of a joint development of variable outflow rate fertilizer application technology.The first and very serious stage in the progress of accuracy of application of the fertilizers was the transition to a liquid form. Its main advantage is the simplicity of controling of the outflow speed.

The spreading of granular forms is much more uneven than applicating of the liquid fertilizers. Technically, you can set a constant rate of leaving of granular fertilizers from the bunker. After that it is necessary for the machine to move along the field at a constant speed, otherwise the fertilization will be uneven. Liquid fertilizers are becoming increasingly popular due to their ability to change the application speed at any moment. Thanks to this, even with the changing speed of the machinery on the field, a constant amount of liquid fertilizer will be poured on each hectare.

The soil tests showed that the concentration of microelements can vary even within the same field. To obtain the maximum yield, it is necessary to create a cartogram of the mineral content in the soil and to apply fertilizers taking this information into account. Further, the data must be stored in an electronic database, on the basis of which the necessary doze of the fertilizer will be found. A separate question, when it will pay off.

To implement this plan, the Farm Dog platform will need to be integrated with the John Deere Operations Center. Initially, the John Deere ExactApply sprayer will work with this system. It is expected that the combination of the production capacities of the two giants should give some result in 18 months. The work will be conducted simultaneously in Israel and in the state Iowa.

Spraying computer «Vodoley» synchronizes the rate of pouring out of the working fluid with the speed of the sprayer. Therefore, even at a non-constant speed of moving the sprayer across the field, the application rate will be constant on every hectare. The GPS module allows the computer to juxtapose the coordinates of the sprayer with the speed of the outflow at a given point in the terrain. This information is stored to the Agrosystem's database.

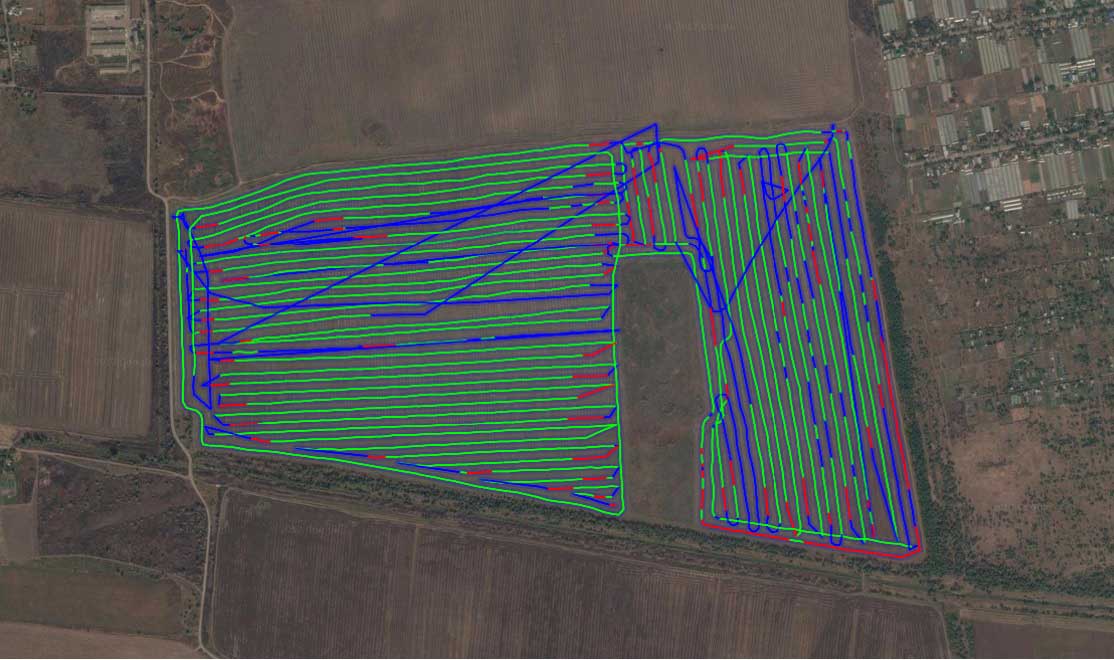

After logging into personal account of the Agrosystem, the owner of the technics, equipped with a computer «Vodoley» can see a picture similar to the one above. You can accurately track the trajectory of the movement of sprayer during work, which will tell a lot about the quality of the work done. The image shows that some trajectories are not very smooth – the driver was not very accurate. This means that there will be gap sites of the territory or the places of reapplication. To avoid this, it is advisable to use the guidance display «Vodoley 2».

Another source of information – color of tracks. Green informs that the liquid fertilizers outflow speed was correct, blue – that there is insufficient application, red – outflow was more than planned.

The subsequent analysis of the yield on the field will show how well the fertilizer dose was chosen. The information about each processing is stored in the database of the Agrosystem and simplifies the further planning of field processing.

Spraying computer «Vodoley» is included in the scope of delivery of self-propelled sprayers «Vodoley» 1 and 2, and can also be installed on other technics as part of a modernization service for agrotechnics (cultivator, seeder or disc harrow). Upgraded in such way technics can applicate liquid fertilizers at the same time as performing typical tasks.