The quality of processing depends on the sprayer boom. Its design should provide the ability to handle at different heights, dampen vibrations, protect communications and spray nozzles from damage in the event of a collision with the ground or obstacles.

When the sprayer moves across the field, longitudinal and vertical oscillations occur. The first, longitudinal, during acceleration and stopping of the sprayer - if the length of the bar is large, special engineering solutions are needed that will protect the structure from destruction. If such fluctuations continue while driving, this is fraught with a violation of the uniform processing of the territory.

The ends of the rods should ideally be protected in case of a collision with the ground, for which, at the moment of the impact, they turn back and gradually return to their normal position. Similarly, the mechanism that protects the bar from a collision in the presence of poles, trees and other obstacles on the field works. But his task is to pull the bar back, not at the expense of the collision itself, but to prevent the possibility itself.

Vertical oscillations of the sprayer boom may occur when the wheels hit the unevenness of the soil, or when making a turn. This is an undesirable phenomenon, since the accuracy of the application is disturbed, there is a risk of mechanical damage to the crop, plants and the rod itself. The first variant of protection is the pendulum suspension of the sprayer boom. It allows you to extinguish spontaneous fluctuations, but does not allow processing on the slopes. Another protection option is already against the consequences, these are various props that, when colliding with the ground, take a hits energy on themself.

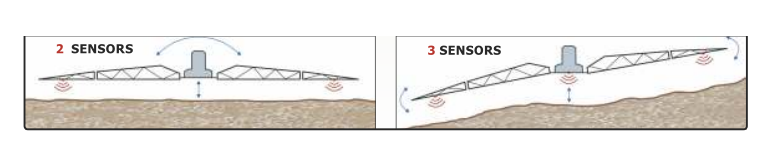

When processing a field located on a slope, another problem arises. In order for the bar to be parallel to the soil surface, we need ultrasonic height sensors and a special mechanism to hold the bar at the right angle. Some modern models of sprayers have a mechanism of temporary raising one/two rods by 30° to protect against collisions with objects and obstacles on the field. This process is controlled either by the driver from the cab, or by the signal of all the same ultrasonic sensors.

Today there are quite a few options for the structure of the sprayer boom themselves. The main load with which it must cope is the cyclic fluctuations that occur when the sprayer wheels interact with uneven ground. To protect the fluid supply hoses, flowmeters and boom sprayers, they may be hollow inside. In this case, even when colliding with the soil, the nozzles and hoses will remain intact.

Another version of the structure is a triangular pyramid (as seen from the side), inside which are all the main elements. The material for the manufacture of rods - aluminum, steel, and combinations thereof. Since the designs of these materials have already reached the limit of possibilities, the developers are eyeing the carbon as a possible successor to metals.

Another feature of the sprayer boom is the need to transfer it from the traveling position to the working position and back. For what each of the rods is formed at the points of assembly. The more points, the more compact the rod will be in the folded position, but the reliability and strength of the structure decrease. In the folding areas, measures should be taken to protect the hoses and wires from damage.

Most sprayers have a boom at the back. In the absence of electronic means of controlling the movement of the working fluid, the driver will not see the moment of clogging of individual nozzles. If the device to control clogged nozzles is installed on the sprayer then the driver immediately learns about the problem. Сlogged spray nozzles will be visible on the device screen. If the sprayer boom is located in the front, then the driver has the ability to visually monitor the permeability of the sprayers, which slightly improves the quality of treatment. But it will distract from other tasks and this approach is worse, because it allows you to see only a complete violation of the fluid outlet.

As already mentioned in the article «Choosing spray nozzles…» a special stand is used to assess the quality of work of sprayers. So you can detect a deviation already in 10% of the normal cross. It is impossible to determine this value visually by observing the spray cone. If something is determined visually, then the permeability is violated much more and the sprayer is already subject to urgent replacement.

Raising the rod for every 10 cm means an increase in losses from wind demolition and evaporation by 2 times. This was discussed in more detail in the article «What is the best height of the sprayer boom». But you need to understand from what exactly this distance is considered. If we are talking about the treatment of spikelets with fungicides, then we take from the average height of the spikelets. When it is necessary to process the land, the ground will be the reference point. When cultivating a field with a potato beds, it is very difficult to calculate and any value is approximate. But if it is necessary to process corn, then it is obvious that the height of the rod will be about 2 m from the surface of the earth.

If the characteristics of the chassis of a particular sprayer allow processing of tall crops, then the boom should also provide for the possibility of lifting and working at an appropriate height. That is, the desired lifting range will be 0.5-2.67 m.