The content of the article:

For convenience, modern sprayers has a different colors, which corresponds to the volumetric flow rate (the amount of fluid that can pass through this sprayer per unit of time at a fixed pressure).

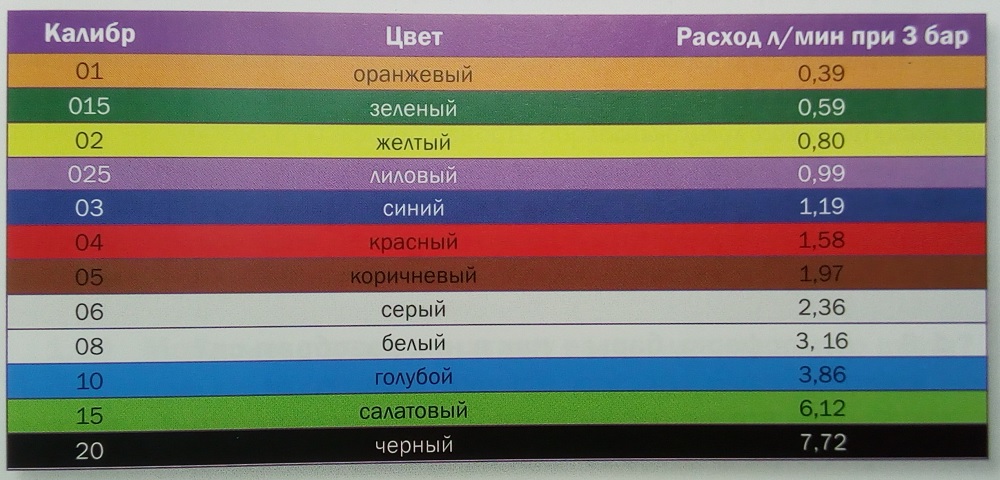

The table below allows you to compare spray nozzless by their color and flow rates. This system originated in the USA and therefore the number (caliber) of this spray nozzle shows the permeability in gallons. That is, the number 01 means that in 1 minute at a pressure of 3 Bar, 0.1 gallons of water will pass through this sprayer.

Since 1 atmosphere is equal to 1.013 bar, it can be considered in more familiar to us units - atmospheres. Such color marking is mandatory for most manufacturers from the EU and the USA.

For uniform treatment of the territory, spray nozzles with the same number should be installed on one sprayer boom. Otherwise, the quality of processing will be unpredictable. During operation, it is sometimes necessary to replace the spray nozzle, when, after an unsuccessful turn, the boom hit the ground and the spray nozzle crashed. It is highly desirable that instead of the broken one, a serviceable one with the same number should be installed.

At the time of manufacture sprayers have a certain capacity. In order to receive a certificate in Europe, the actual consumption of the spray nozzle should differ from that stated in the documents by no more than 10%. The list of such spray nozzles certified for sale in Germany is called «Tabelle der JKI anerkannten Pflanzenschutzdusen» and is available for download at the link. It is better not to buy models that are not on this list at all - their coefficient of variation probably exceeds 10% already at the time of manufacture. As exploitation proceeds, the internal geometry of the channel through which the working fluid passes varies. Some fertilizers have a pronounced abrasive effect. Therefore, before starting work and after it is completed (and periodically during the work season), it is advisable to check the condition of the spray nozzles.

If two consecutive spray nozzles on the boom show consumption by 10% more than the standard, then it is recommended to change all them at once. Due to non-uniformity of wear, one should not expect that all of them will evenly increase throughput by 10%. Those located closer to the center will be worn out more - the pressure is higher there. Wear and tear will also affect the shape of the spray head, which will also become uneven.

In Europe, it is mandatory to regularly check the sprayer for the throughput of spray nozzles. If the flow rate of sprayers varies by more than 10% within the boom, then working on this sprayer is prohibited.

Thus, at a speed of 10 km/h (166 m/min), the sprayer will process a hectare in 3 minutes. With a pressure of 3 atmospheres, 40 nozzles will spill 143 liters during this time. To pour the norm (150 l/ha), it will be necessary to raise the pressure quite a bit from the optimal one, which practically does not change the size of the droplets for a given caliber of spray nozzles.

The article «Pressure in the working system of the sprayer and the quality of treatment» has already wrote about the effect of pressure on the size of the droplets. It is unacceptable to increase the pressure above the upper permissible and therefore if the planned outflow rate is 250 l/ha, then spray nozzles No. 5 should be used. Calculation below.

To shed 250 liters will have to slightly increase the pressure from the optimal value (3 bar).