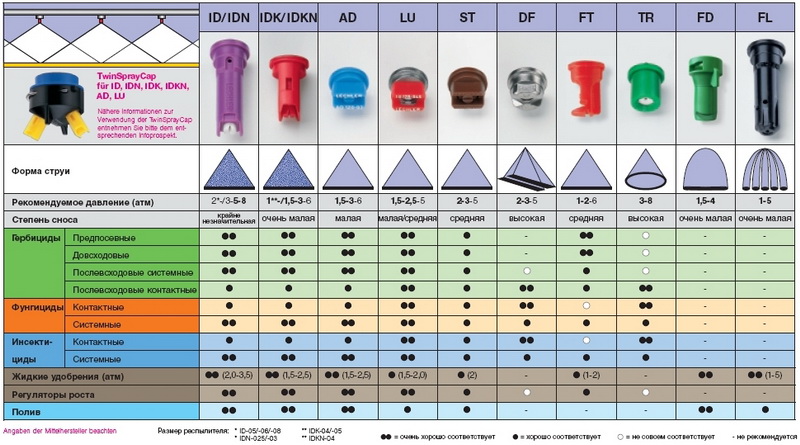

The quality of processing of the entire field depends on the correctness of the selection of the spray nozzles. It is individual for the every field! For each specific task, you should select spray nozzles separately. Today there is a huge variety of spray nozzles (see image below), so in this article we will look at the fundamental differences between single- and twin-flare spray nozzles.

In order to get the maximum yield with minimal costs, you need to use a spraying computer and a high-quality working fluid supply system. The spraying computer maintains the constancy of the flow rate when the sprayer speeds fluctuate. Spray nozzles «responsible» for exactly how this area will be processed.

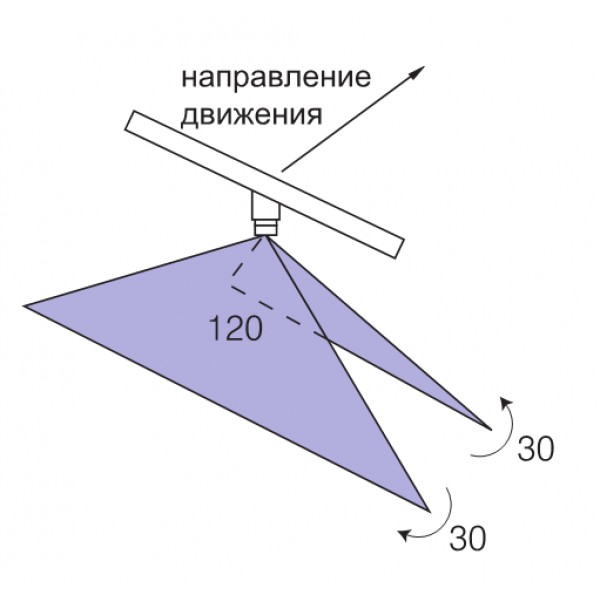

Spray nozzles (today) are single and twin-flare. They should be used in different situations. Twin Flat gives two spray flares: first is directed forwars and second - back. The angle between them is 60 degrees, relative to the soil - 30. As a result, it is well suited for the treatment of the spikelets(protection against fusarium) - two flares provide treatment for upright stems on both sides.

You can use two-flare spray nozzles to applicate a herbicide in the root zone for cereals only before and during the tillering stage. When the tube stage starts, for the treatment of the root zone use only single-flare spray nozzles.

Two-flare sprayers are ideal for treating upright plants, including when weeds have reached the same height as the crop. This treatment allows you to maximize the effectiveness of the contact component of the pesticide.

This treatment is well suited for beets after the 4-leaf stage, because, flying at an angle, some of the drops will fall under the leaves of the beet itself.

Two-flare spray nozzles can be solid and with interchangeable heads. In the second case, you can combine - put the same numbers of nozzle back and forth and different, for example, send larger drops forward, and smaller ones back. This option allows you to better handle the field with dense vegetation.

It become clear, that when it is necessary to «punch» the entire stem to the ground, one-flare spray nozzles should be used. To protect the grain from weed overgrowth after the tillering stage (the phase of entering the tube) only single-spray nozzles are used.

Presented by two groups: slot and injection. Slotted holes are often cheaper, what call additional interest. But they give a lot of small drops, which reduces the quality of work in dry and windy weather.

Injection type of spray nozzles give a more uniform spectrum in size, they make fewer small droplets, which gives better resistance to wind drift.

Processing in high winds: possible only with single-jet injection nozzles, the pressure in the system should be closer to the minimum allowable and the boom height is lowered to 40 cm. This is relevant for some regions where the wind blows constantly or for a situation when it is impossible to wait for better weather.

The general rule for the operation of spray nozzles is as follows: with the same pressure, as the serial number of spray nozzles increases , the droplet size is larger (the outflow rate too). That is, the number 04 will give larger drops than the number 03 at a pressure of 3 Bar. But a series of IDKT spray nozzles (single and two-flare) work «vice versa». With the same pressure, as the serial number of the sprayer increases, the size of its droplets decreases. But increasing the number of drops. That is, they are not suitable for the root introduction of the liquid fertilizers, but only for foliar nutrition of plants and spraying plant protection products.

In practice, there are situations when there are several spray nozzles with different serial number on the same boom, which the driver took from «his personal emergency collection» in the cab. They are stored just in case to replace the failed one directly on the field. On the one hand, than to stop processing altogether, it is better to at least somehow complete it (at least one lane to the end of the field). But to begin work with such a «traffic light» is unacceptable - when time passes instead of a uniform green field, you will get a zebra. The term «traffic light» appeared due to the fact that the nozzles with different throughput differ in color, which catches the eye on the rod.

When using a suction hose from an untested manufacturer, air may enter the working fluid supply system. This disrupts the normal operation of the sprayer.

When air enters the system, flowmeters will start to make mistakes, and the nozzles will «spit», regardless of their design. Seeing this, take action - check and, if the reason is there, replace the pump inlet hose. Otherwise, keep the rate of outflow at the required level will not work.

The main task of the inlet hose is the isolation of atmospheric air from the intake fluid, and not just the absence of leakage of working fluid. Cheap counterparts do not let in liquid and pass gases. By the same principle, water-repellent fabric is arranged. As a result, the pump supplies the system with working fluid mixed with air and the system cannot maintain the required flow rate.