To get the most out of invested money, it is more rational to use liquid fertilizers. The spraying computer «Vodoley» gives a saving the liquid fertilize, at the expense of synchronizing of the outflow rate of the working fluid with the speed of the technics That is why, more and more farmers are switching to liquid fertilizer forms.

Another important point of saving – in one tank it is possible to mix liquid fertilizers, UAN and plant protection products, so that in one pass the sprayer do several types of processing at once. But in any case, to use a liquid form of fertilizer you will need a sprayer. What models are now on the market, and how they differ?

Let's start with the DAMMANN line, which includes trailed and self-propelled sprayers.

Immediately have to note that the «smallest» of the DAMMANN trailed sprayers is equipped with a tank for 3 or 4 thousand liters. If you add here the weight of the unit itself, the fully-equipped aggregate will weigh at least 5 tons. That is, passing through the field, he will make a rut.

Of course, the rut will make a tractor too, which should drive a trailed sprayer. The width of the boom from 15 to 28 meters. The average speed of movement along the field is 25 km/h.

There are models designed for a tank capacity of 5800 liters, 7000 liters and 14000 liters.

Different models have additional options in the form of a tank for washing hands and other elements. Management of the system of supply of working fluid electronic. In order for the driver to operate the sprayer from the cab, it may be necessary to install additional equipment on the tractor.

Self-propelled modifications are known, first of all, by giant representative «DAMMANN-trac DT 3500H S4 EcoDrive». When the tank is fully loaded, with a capacity of 12,000 liters, it can weigh 25 tons. Even with all his 6 wheels, he will inevitably create a rut. The range of the rods is 30-42 m, which, on the one hand, allows covering a large area in one pass, on the other hand, on a field with power towers, the sprayer trees can not be able to process the whole surface.

Thus, this model is the choice of farms, where there are large and very large areas of soil, which need to be treated with a liquid fertilizers or an PPP.

Of course, in the range of self-propelled sprayers DAMMANN there are easier options, designed to work with smaller areas. Unlike trailed, all self-propelled modifications move independently from tractor on the field, which somewhat reduces the load on the soil. But since conventional wheels are used, the track from passing such a technique across the field will be.

Of course, in the range of self-propelled sprayers DAMMANN there are easier options, designed to work with smaller areas. Unlike trailed, all self-propelled modifications move independently from tractor on the field, which somewhat reduces the load on the soil. But since conventional wheels are used, the track from passing such a technique across the field will be.

In total, the advantages of this line include its technological equipment, user-friendliness (especially for the driver), electronic control of the outflow.

What should the agrarians take into account when using such a technic – if the need for repair arises, then its price will be high. Most parts replacement operations must be performed at authorized service centers. Repair, too, can not be performed independently, ideally, if something has ceased to work it should be replaced under warranty.

Since the manufacturer of this brand is in Europe, the purchase of the necessary components will be costly. Therefore, any breakdown can be not only a costly event, but also severely delay the execution of work.

This is a very respected trademark, which, above all, is known for its line of tractors.

For the entire line, you can note the intelligent control of the fluid outflow and the process of supplying the working solution. The width of the processing bands varies from 18 to 36 meters. The volume of the tank from 2300 liters to 4500 liters. The outflow rate is 640 or 870 liters per minute. Depending on the model, engine power can be from 173 hp, up to 346 hp.

When the model is equipped with AutoTrac and Section Control, the sections of the rods are automatically switched off, which can prevent spraying of the working fluid onto the already treated sections, road, irrigation channels.

When the model is equipped with AutoTrac and Section Control, the sections of the rods are automatically switched off, which can prevent spraying of the working fluid onto the already treated sections, road, irrigation channels.

The end sections of the rods are protected from damage with the rotary mechanism. After a collision with the ground, the end section deflects backwards and upwards and then returns back.

Pneumatic suspension ensures smooth running of the whole unit. The ComfortCommand driver's seat is designed to ensure stability of the body during operation, which reduces fatigue and facilitates working conditions.

Sprayers of this brand are represented by the 9M and 9P series. For each of them there are three tank capacities – 3000 liters, 3500 liters, 4000 liters. The «dry» weight of each machine is about 7 tons.

The driver's cab is located in the front, the rods are at the rear. The driver has a good view during operation, with only one correction, you need to take into account the height of the cabin above the ground. The ride height of 1.55 m makes it possible to move along the field with sunflower or corn. Optional clearance is 1.7 m.

The range of the rods is 30 meters. Sprayer is designed to handle large areas. Electronic control of the supply of working fluid.

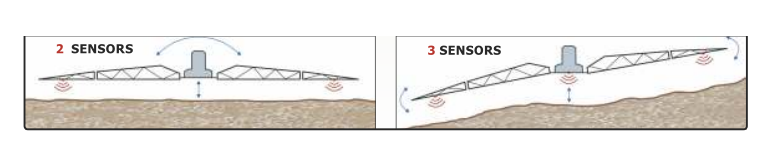

Depending on the configuration, 2 or 3 sensors can be installed that control the height of the rods above the ground. When moving across the slope this allows you to keep a constant distance to the ground for each bar (right and left). As it is easy to guess, 3-sensor system costs more (about 3 thousand euros).

In general, the pluses of this brand of sprayers should be suitable for large farms. Thanks to the system of rod alignment, it should be evaluated by those who have land is located on the slopes.

The disadvantages are the cost, both in the base version, and top. Also, maintenance and repairs will be expensive. In the process of operation, it is possible to purchase additional components, the price of which is calculated exclusively in euros. A significant weight of this technique will lead to the appearance of a rut.

Representatives of this line are quite large in size. The RG 1100 model is equipped with a 338 hp engine, a 4088 l tank, and a RG 1300 – 370 hp a tank for a 4,770 hp utility.

The height of the rods above ground level can vary from 78cm to 210cm. An interesting feature of this line is variable width between wheels, which can be changed from 304 to 386cm. Ground clearance 122cm. Pneumatic suspension provides high stability of this technique when driving on a field with a complex terrain.

Filling the tank with liquid fertilizer is done from the front so that you do not have to fold the rods, approaching the edge of the field, where the fertilizer is being filled with new fertilizer.

The boom range is 30 and 36 m. The second model is equipped with a rod height sensor above ground level.

Estimated pace of work – 600-1500 ha per day.

Common points to consider when using heavy sprayers.

A common problem with the use of wheeled vehicles is the need to have dirt roads covering the field at distances that depend on the span of the sprayer arms. Otherwise, this technique will still leave a rut with damaged plants.

Another thing that the agrarians regularly have to face is the different size and shape of the field, the presence on the field of various obstacles, in the form of power lines, trees. The rectangular shape of the field is common, but it can also be another, in which case the sprayer with long rods will not be very useful – at the edges will be the mass of untreated areas.

A heavily wet soil in general may not available for processing by the heavy equipment! Or the crops after such passage will be simply destroyed.

Given the above problems, the company «Comprehensive AgroService» developed a self-propelled sprayer «Vodoley» with an on-board computer equipped with a GPS module. The main advantage of this sprayer – low weight with extremely high cross-country capability.

Ultra-low pressure tires have minimal impact on the soil (not more than 160 g/cm²), what allows:

Ultra-low pressure tires have minimal impact on the soil (not more than 160 g/cm²), what allows:

The process of applying liquid fertilizer forms is controlled by the on-board spraying computer «Vodoley». Its main task is to synchronize the power of the pump with the speed of moving the sprayer across the field. Thanks to this, even with fluctuations in the speed of the machinery, the level of application of the active substance per hectare remains at a given level.

Filling with working fluid is carried out from the front, which makes it possible to perform it as quickly as possible without the need to fold the rods.

Filling with working fluid is carried out from the front, which makes it possible to perform it as quickly as possible without the need to fold the rods.

During operation, the speed and position of the sprayer on the field are determined by GPS and can be viewed both in real time and later in the agricultural management system. All reports are stored and later available for analysis for the consumption of diesel fuel, working fluid, time spent.

The computer takes into account and preserves many parameters of the sprayer's operation: the amount of spent working fluid and the rate of its consumption, the distance traveled, the speed of movement.

Japanese engine «Kubota» (volume 1.5 liters or 2.4 liters) guarantees trouble-free operation for a long time.

Equipping the sprayer «Vodoley» with the hydraulic boom opening system, allows the driver to switch rods from the transport mode to the working mode without leaving the cab. This especially saves time, when you need to process a lot of plots of land, located so that you have to move on ordinary roads. It is possible to change the height of the rods relative to the ground within 0.5-1.8 m. The end sections of the rods protects them from the collision with the soil through the possibility of turning back to 45°. in the horizontal plane.

Thus, the self-propelled sprayer «Vodoley» is a high-performance solution for the application of liquid fertilizers, UAN, PPP. In addition to the ability of working in all weather conditions and with any ground condition, it accurately maintains a predetermined outflow rate for each treated hectare. The data of its work is saved and later can be viewed for analysis. At the same time, the fuel consumption does not exceed 0.3 liters per hectare (for the engine 2.4 liters) and 0.2 liters per hectare (1.5 liters).