How strange it does not sound, but developed countries are experiencing a shortage of labor in agriculture. After all, we are talking about qualified personnel, not temporary employees. This is what contributes to the active growth of agricultural robotization. And without this, the highly demanding industry needs more and more solutions.

Already you will not be surprised by the using of the GPS technology to determine the location of equipment in the field, where without such an approach, you can simply get lost. To avoid repeated application of the fertilizer on the already treated area, parallel driving systems should be used. But this is not enough – for a more rational approach to the processing of a large territory, following a man-driven tractor, unmanned analogs are going. And one experienced driver leads the «pack» of the machines.

The company Case IH demonstrated the concept of a completely unmanned tractor, which will perform all the work on its own. The use of robots in agriculture can face such problems:

What should interest investors and manufacturers – this market is relatively free. It does not yet have clearly defined standards, and each manufacturer demonstrates its own vision of how it should be. The basic requirements, however, are already there:

In the main industries where robotization can be expected, it is possible to single out livestock, crop production, and related industries.

Automation in cowsheds is no longer a novelty, but every year some of the developers finds, how to surprise. The need for regular cleaning of barns and feeding large volumes of food has made to solve this problem a long time ago, but «there is no limit to perfection». From a simple mechanical feeding technology, they stepped to computer accounting and analysis of the quantities of substances fed. Since rational nutrition includes quite a few components, accounting becomes a complex task.

To maximize milk yield it is neccessary to have the possibility of comparing of the quality and quantity of the produced milk with the type of feeding of cows.

Depending on how much substances are already in the soil and the needs of the culture that will be grown here, a dose of fertilizers, which must be introduced, is calculated. But here lies the source of the losses – a simple spreading of granules on the field entails a partial loosing of the fertilizer. When using the plant protection products, the situation is even more dramatic – they must be applied on the exactly on the weed, not on ground. And here robots will be especially useful.

If the robot detects a plant that needs a fungicide, then it can apply the drug exactly on this plant, simultaneously making a video recording of this event, with the preservation of the coordinates of this place. That will allow to make a detailed map of the spread of weeds. Simultaneously, these same robots can evaluate the state of the growing culture, detect signs of a deficiency of nitrogen, phosphorus and other substances. Based on the work of observing robots, will act others – those that introduce fertilizers the need for which has been identified.

AgBOT II already demonstrates the approach with video fixation of the weeds. Moreover the company RoboCrop, offers a complete rejection of the plant protection products. In case of detecting of the weed, it is simply destroyed on the spot, for example, by a laser. The approach is more than interesting, as it reduces environmental pollution.

One of the variants of such a plan is the Thorvald platform, developed by groups of Norwegian and British scientists. It is equipped with a GPS module, various sensors, allowing it to assess the condition of plants.

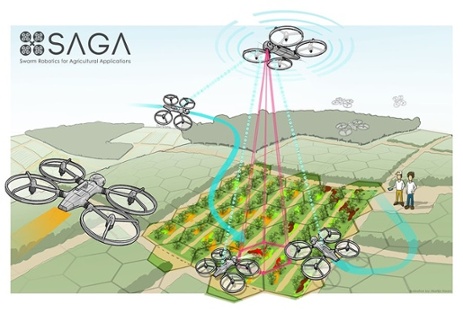

Assessment of seedling quality can be performed with the help of UAVs or other devices. Since you need to process large areas, then any savings will come in handy. Small UAVs will consume less fuel than human-piloted vehicles. If the management of this technique does not require human intervention, it can work around the clock, without interruptions and days off.

The irrigation of the whole field also is less profitable in comparison with the point introduction of water. In certain regions, this can be very much in demand.

The companies HETO Agrotechnics and Harvest Automation demonstrate their approach to solving of the problem of labor shortage. Their findings should help in growing seedlings. Regular care, watering and processing of the latter requires very great effort and takes a lot of time, even with qualified personnel, so automation is very in demand.

Automated systems for collecting grain are already taken for granted.

Harvesting – one of the few industries where technics can not be universal. The need to visually distinguish already ripe fruits and vegetables forces us to use systems with video cameras. Machines for harvesting strawberries, potatoes and cucumbers differ radically. The only thing that unites them is the need to harvest fruits without their mechanical damage, like the way human hands do it.

Wall-Ye – a recent development demonstrating the latest progress in harvesting. Agrobot – another system for harvesting strawberries.

In general, the growth of technologies related to data processing promises new opportunities in this direction.